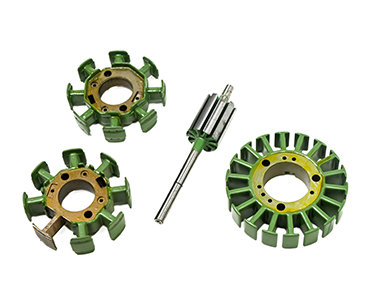

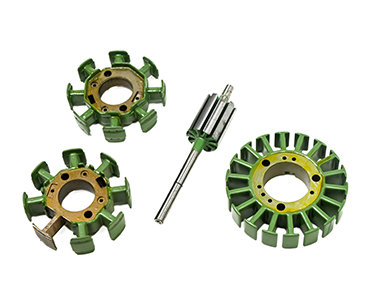

Armature Powder Coating

Armature Powder Coating

Armature Powder Coating is a specialized process used in the manufacturing and maintenance of electric motor armatures. The armature is a crucial component of an electric motor or generator, consisting of coils or windings that rotate within a magnetic field to convert electrical energy into mechanical energy or vice versa. Powder coating is a method of applying a protective layer to the armature to enhance its durability, insulation properties, and overall performance.

Armature powder coating is the application of a dry powder to the surface of the armature components (such as the rotor, windings, or lamination stacks). The powder is then heated to form a hard, durable coating that serves multiple purposes, including insulation, protection from corrosion, and thermal management.

Applications of Armature Powder Coating

- Electric Motors: Armature powder coating is extensively used in the manufacturing and repair of electric motors, where it provides insulation and protection for the windings and rotor.

- Generators: In generators, powder-coated armatures are essential to ensure the efficient transfer of energy and to protect the components from wear and corrosion.

- Automotive Motors: Electric motors in vehicles, including fans, wipers, and power steering motors, benefit from armature powder coating due to its insulation and durability properties.

- Industrial Machinery: Many types of industrial machinery with rotating armatures use powder coating to protect against dust, moisture, and mechanical stresses, ensuring long-term reliability.

Types of Powder Coatings Used

- Epoxy Powder Coatings: These coatings offer excellent adhesion, electrical insulation, and corrosion resistance. They are commonly used for applications requiring high dielectric strength, such as armature winding insulation.

- Polyester Powder Coatings: Polyester coatings provide excellent outdoor weathering and UV resistance. They are typically used for applications exposed to outdoor elements.

- Hybrid Powder Coatings: A combination of epoxy and polyester, hybrid coatings provide a balance of performance in terms of both corrosion resistance and heat tolerance.

Advantages Over Traditional Coatings

- Higher Efficiency: Powder coating provides superior coverage and adhesion compared to traditional liquid coatings, resulting in better overall performance of the armature.

- Longer Lifespan: The durability and resistance to environmental factors mean that powder-coated armatures last longer, reducing the need for frequent repairs or replacements.

- Cost-Effectiveness: While the initial setup costs for powder coating may be higher, the reduced need for maintenance and replacements leads to long-term savings.

Armature powder coating is an essential process for enhancing the performance, protection, and longevity of electric motor armatures. By providing insulation, corrosion resistance, and heat protection, it helps ensure that motors and generators operate efficiently under demanding conditions. With its environmental benefits, high durability, and cost-effectiveness, powder coating has become the preferred method for finishing armatures used in a wide range of industries, from automotive to industrial machinery.